Repair of the cracked mounting flange on the

gearbox housing of a wind turbine

Fastening flange in the broken state

Suggested repair by inserting an insert

Cracked mounting flange drilled off approx. 80mm deep and grinding clean. Recordings for the steel locks introduced Measured mass for the insert

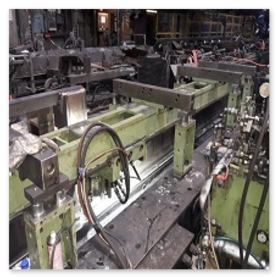

Insertion of the steel construction and establishment of the non-positive connection

Manufactured steel construction fitted and in the base body, drilled out and riveted

Insertion of our standard keys, riveting and unscrewing the gap between the base material and the steel construction, screwed in screws caulked

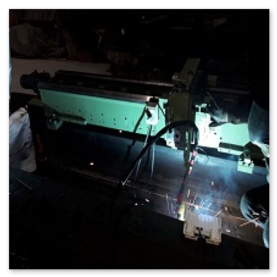

Mobile processing of the steel construction

Milling device used fastened and aligned

laser tracker for measuring the surfaces and holes as well as aligning the Milling device

Milling off the surface of the steel construction used on the Level of the upper mounting flange

All threads are inserted and the outlines of the steel construction are aligned with the base body by grinding

Repair point deleted